Universal gauge for MS3, MS3Pro, Ultimate, MS2, Microsquirt - Perfect Tuning

The Perfect Tuning Universal Gauge is a new product. The gauge is compatible with all the Megasquirt ECU except the Megasquirt 1:

I'm running the Perfect Tuning gauge in the white truck, and wondered who else here is using it? I have it mounted in a single gauge pod on the A-pillar and installed it with no irreversible modifications to the truck's interior.

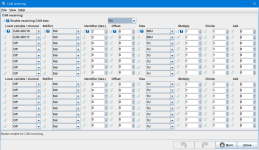

I've recently gotten the gauge to run a pressure sender for fuel pressure, and will install a second one for oil pressure. The gauge is communicating the pressure values to the PxS for datalogging, and I'll post a how-to on that to this thread shortly because some of it took some "that's not apparent" from tech support (which was very responsive).

The alarm features in the gauge are pretty awesome, too.

I'm trying to figure out how to get the PxS to communicate transmission temperature to the gauge (the PxS can send a ton of information to the gauge, but since running an E4OD isn't a normal MS3 function, it's not one of the values included in the list). I've gotten it to send the internal ADC02 value that comes from the microsquirt that runs the transmission, but that's a raw number that is showing resistance or something, so it's a decreasing curve rather than an increasing line, and thus not particularly useful.