Now that I have spark again, it dawned on me that I've cranked the engine a number of times so trying to put the distributor back in the same position is completely pointless. Any tips, or pointers, or directions on how to time this thing as if it was just assembled?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Timing an Engine

- Thread starter lightngsvt

- Start date

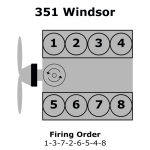

As you look at the front of the truck the #1 plug is the front left plug. Remove it, then pop your finger in the hole and with a long breaker bar slowly rotate the engine clockwise. As you move closer to top dead center (TDC) you'll feel compression against your finger. This should correspond with 0 degrees on your balancer, go ahead and finish moving it to 0 should not be far off. Now you've established TDC on the compression stroke, drop your distributor in and line the rotor up with a plug wire post on the cap. That post starts the #1 cylinder firing order and now you follow the firing order counter clockwise. See the picNow that I have spark again, it dawned on me that I've cranked the engine a number of times so trying to put the distributor back in the same position is completely pointless. Any tips, or pointers, or directions on how to time this thing as if it was just assembled?

IT'S ALIVE!!!!! And I fixed it! The electric fan is even working properly. It runs with stock ignition and with the Crane. Should I remove the Crane before I make everything nice again (wiring)? Or leave it since it works? At least now I know how simple the wiring for it is. The entire time it was just a bad MSD coil.

Thank you, Raymond. Between your post and Google searching, I found the info I needed. I didn't know that the small tooth on the reluctor wheel (?) inside the distributor needs to be lined up with the black sensor in the distributor. I was getting it lined up with what I thought was #1 but it was off by about 1/4". Lined that up, pulled the spout and she fired up! I got the base timing set to 10* btdc.

Also, big thanks to Jeff and everyone else who offered help!

Of course, the shop that had didn't actually tune it up at all. I did a base idle reset, the truck wouldn't idle without the IAC, so I dialed that in. Then I checked the TPS voltage and it was at 1.095v, so I got that down to .98v. Then I pulled the battery and let the truck sit. I'm about to go attempt to drive the thing now!

With me and this truck, there's never good news without bad. It's already leaking oil and trans-fluid. I'm going back and putting this on him to fix since they pulled and had the trans fixed. Depending on what's leaking oil it may be them, or it may be from the engine builder. I'm either going to have him fix it, or pay me to have someone else fix it.

But I can say that I am happy, and I feel good that I took this truck apart and put it back together running better than it did before!

Last edited:

Agreed!I would NEVER go back to the place you had it at before.

I totally get what you are both saying. The only reason I even said that is I shouldn't have to pay to have it fixed.

I certainly agree with that, but you shouldn't have to wait years for your truck either! Where is it leaking and how bad?I totally get what you are both saying. The only reason I even said that is I shouldn't have to pay to have it fixed.

I certainly agree with that, but you shouldn't have to wait years for your truck either! Where is it leaking and how bad?

Oh I agree! Zero excuse it took 2+ years AND I had to fix stuff when I got it back. I haven't even looked yet to see where the leaks are from. One thing at a time, today was getting it running again and taking it for a 15 mile drive.

Way to go, Chuck!

It's not unusual at all for the valve covers to need to be retorqued after a few heat cycles. I have found that, while it's a hassle, it's best to drive a few hundred miles on a fresh build, then take the upper intake off and torque the intake manifold and valve cover bolts. You'll save yourself from weird oil and coolant leaks down the road, which would eventually require removing the upper anyway.

I'd leave the Crane since you'll eventually need the boost retard function, just be aware that they do fail, and sometimes in strange misfire ways.

It's not unusual at all for the valve covers to need to be retorqued after a few heat cycles. I have found that, while it's a hassle, it's best to drive a few hundred miles on a fresh build, then take the upper intake off and torque the intake manifold and valve cover bolts. You'll save yourself from weird oil and coolant leaks down the road, which would eventually require removing the upper anyway.

I'd leave the Crane since you'll eventually need the boost retard function, just be aware that they do fail, and sometimes in strange misfire ways.

Pretty sure it's more a loose valve cover, but hopefully, that's all it is. See pic.

I had something weird happen yesterday, after I got it running I noticed it was really low on gas so I decided to drive to the gas station. While I was driving it just died, no sputter, just died. I coasted to the shoulder, cranked, no start. I checked all the connections, all tight. I decided to plug the stock ignition back in and it fired back up and I quickly got to the gas station. After that, I was able to drive 15 miles with no issues. But now I'm kind of spooked to run the Crane again.

I had something weird happen yesterday, after I got it running I noticed it was really low on gas so I decided to drive to the gas station. While I was driving it just died, no sputter, just died. I coasted to the shoulder, cranked, no start. I checked all the connections, all tight. I decided to plug the stock ignition back in and it fired back up and I quickly got to the gas station. After that, I was able to drive 15 miles with no issues. But now I'm kind of spooked to run the Crane again.

Attachments

Ug, front seal on the transmission. Boo. Oil, I'm willing to bet passenger side valve cover. It can run to the back of the head and then down the side of the block behind the header flange.

Ditch the Crane. You'll need to find a different way to control timing prior to running boost, but the Crane is just an additional failure point.

I still have that A9 compatible plug and play AEM computer and MAP sensor if you ever want to give it a try.

Ditch the Crane. You'll need to find a different way to control timing prior to running boost, but the Crane is just an additional failure point.

I still have that A9 compatible plug and play AEM computer and MAP sensor if you ever want to give it a try.

Last edited:

You think front seal on the trans? The front pump was replaced after the converter incident. So that's a trans-out service.

If it's a valve cover, that should be easy to fix. Maybe it just needs to be tightened.

Yeah, after the truck died while driving, I have zero trust in the Crane. I'm going to ditch it. Don't know what to do about timing control whenever the Vortech goes on? I wonder what Jamie did? Maybe it'll be time to go PimpXs, I'm starting to feel a little more confident, and I think you said it only 3 wires to repin and add a MAP sensor.

If it's a valve cover, that should be easy to fix. Maybe it just needs to be tightened.

Yeah, after the truck died while driving, I have zero trust in the Crane. I'm going to ditch it. Don't know what to do about timing control whenever the Vortech goes on? I wonder what Jamie did? Maybe it'll be time to go PimpXs, I'm starting to feel a little more confident, and I think you said it only 3 wires to repin and add a MAP sensor.

If you use the PimpX without the transmission control, it's plug and play for the A9x. You just screw it in and run a piece of tubing to it (it has a built-in MAP sensor). If you want want wideband (and you do), then it's a little more effort, but you can still do it plug-and-play. I have the wideband in my white truck using the stock O2 sensor wiring.

THEN comes the tuning part. But that's more the techy side of thing, so may be right down your alley.

THEN comes the tuning part. But that's more the techy side of thing, so may be right down your alley.

@Raymond_B I said PxS in my post. I think Jeff was suggesting the Px because he knows how I feel about any type of wiring, and its straight p-n-p. But you are right, that trans controller is old enough to drink legally now, LOL, and it would be best to have a more modern means to control the trans whether it is PxS, or a new Quick4.

@FMOS Racing For WBO2, I have the new Innovate digital WBO2/Boost pressure gauge (which of course doesn't work. Have to remove it and send in for repairs). I assume I could tie that into the Px/PxS? Would you have any base tune files from your red truck that might be close enough that I could start with, if you'd be willing to share?

I won't be changing it today, but maybe a winter project.

@FMOS Racing For WBO2, I have the new Innovate digital WBO2/Boost pressure gauge (which of course doesn't work. Have to remove it and send in for repairs). I assume I could tie that into the Px/PxS? Would you have any base tune files from your red truck that might be close enough that I could start with, if you'd be willing to share?

I won't be changing it today, but maybe a winter project.

The Innovate should have a 0-5v output and that's what you'll tie in. I had that gauge in my LS swapped Blazer and really liked it. I was using it to input to the HPTuner, so I remember it having that output.

Our combos are so similar that I should be able to give you fuel and timing tables that will get you a pretty solid starting point. If you're thinking of upgrading the Q4, I'd just go with the PxS. The Q4 has a couple of features that I wish the PxS did, but the total integration of the trans and engine in the PxS makes it overall a better solution in my mind.

I can loan you the "adapter" harness that I made when I was in the process of converting the white truck over and wasn't ready to totally commit. It incorporates the changes that have to be made in the wiring so that you can setup and test the PxS without swapping the leads in the 60 pin harness.

Our combos are so similar that I should be able to give you fuel and timing tables that will get you a pretty solid starting point. If you're thinking of upgrading the Q4, I'd just go with the PxS. The Q4 has a couple of features that I wish the PxS did, but the total integration of the trans and engine in the PxS makes it overall a better solution in my mind.

I can loan you the "adapter" harness that I made when I was in the process of converting the white truck over and wasn't ready to totally commit. It incorporates the changes that have to be made in the wiring so that you can setup and test the PxS without swapping the leads in the 60 pin harness.