You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Things are starting to come together

- Thread starter Raymond_B

- Start date

Very very nice.

Did a bunch of cleanup to get the new pan installed with this printing in the background. It’s a magnetic plug holder, might try printing the font raised to see if it comes out cleaner, but overall happy with it. Magnets hold the plug good, right now they are superglued in, but I need to try embedding them as that is an option in the Prusa. Anyway had fun making this.

Man, what a nice pan, windage setup and all. That thing is like a girdle itself!

OK this pan is NOT plug and play. Luckily I had a good buddy helping me and talking me off the ledge a couple times

Anyway, DART block owners, you'll have to grind down the #2 main studs so the oil pump pickup clears, then you have to move the stud that has the oil pump pickup tube stud and it also took several tries to get the oil pan to pickup screen at the correct spacing from the bottom of the pan. From there the driver's side has o-ring plugs that you have to take out to tighten down the pan rail nut (they give you studs for the DS). On these the back two were super hard to get to and the windage tray screen interfered with getting a socket on them. You have to put grease in your socket so the nut does not fall in the motor as there are no tubes. OOOOF what a PITA. Then the driver's side motor mount (BGY mounts) hit the pan as the pan lip comes out quite a ways from the block. So I had to take a good 1/4 inch off the motor mount. Once it was finally on it seems really solid and cleared the front crossmember, headers, starter, etc. I do not think this will work with stock motor mounts, but I need to measure the front cross member clearance.

Got the motor back in with a TON of help from my friend. Hope to fire it up this weekend.

Here's a few pics.

Main stud clearance work.

Had to move the mains stud that the oil pump pickup bolts to.

Motor mount haircut, back to back to show difference.

It's purdy...

Back in the truck, yay!

Anyway, DART block owners, you'll have to grind down the #2 main studs so the oil pump pickup clears, then you have to move the stud that has the oil pump pickup tube stud and it also took several tries to get the oil pan to pickup screen at the correct spacing from the bottom of the pan. From there the driver's side has o-ring plugs that you have to take out to tighten down the pan rail nut (they give you studs for the DS). On these the back two were super hard to get to and the windage tray screen interfered with getting a socket on them. You have to put grease in your socket so the nut does not fall in the motor as there are no tubes. OOOOF what a PITA. Then the driver's side motor mount (BGY mounts) hit the pan as the pan lip comes out quite a ways from the block. So I had to take a good 1/4 inch off the motor mount. Once it was finally on it seems really solid and cleared the front crossmember, headers, starter, etc. I do not think this will work with stock motor mounts, but I need to measure the front cross member clearance.

Got the motor back in with a TON of help from my friend. Hope to fire it up this weekend.

Here's a few pics.

Main stud clearance work.

Had to move the mains stud that the oil pump pickup bolts to.

Motor mount haircut, back to back to show difference.

It's purdy...

Back in the truck, yay!

Oil pan porn.

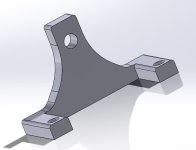

So while I had the engine on the stand I was able to refine the blower brace I've been working on and I believe this will be it's final iteration on placement. I added an additional mounting bolt to the front mount for 3 total and I need to make the engine side part a bit thicker (you can see washers for now), but this should be it. Last pic shows the blower bracket brace final form.

I somehow missed taking a pic, but the strut does not touch the PS pump, it's close but there's a good sized gap. I also installed the accessory belt and no interference with it and the blower bracket brace mount.

I somehow missed taking a pic, but the strut does not touch the PS pump, it's close but there's a good sized gap. I also installed the accessory belt and no interference with it and the blower bracket brace mount.

I would 100% fab an auto tensioner while it's sitting there as well.

Sent from my Pixel 6 Pro using Tapatalk

Added that a few pages back

Jeff, very much appreciate the feedback! I was hoping you'd chime in.Engineer in me says you're going to want a decent sized chamfer or much larger radius fillets on these corners, otherwise you have a pretty big stress riser developing between those areas.

From the manufacturing side that wont be to bad to machine, will just take a decent size piece of stock to begin with.

Straight load from the turnbuckle will be stronger on the center eyelet but neither are ideal for any vertical load, but that also doesn't seem like it will have any vertical load with your design

Thanks Travis! As soon as I get everything finalized I am going to send you the filesFrom the manufacturing side that wont be to bad to machine, will just take a decent size piece of stock to begin with.

Straight load from the turnbuckle will be stronger on the center eyelet but neither are ideal for any vertical load, but that also doesn't seem like it will have any vertical load with your design

Crap, and I thought you did it as well. That's what I get for not remembering.Added that a few pages back

Sent from my Pixel 6 Pro using Tapatalk

Crap, and I thought you did it as well. That's what I get for not remembering.

Sent from my Pixel 6 Pro using Tapatalk