Hey all,

I've got some questions. I'm at the spot to install the wideband. I got the AEM gauge and sensor.

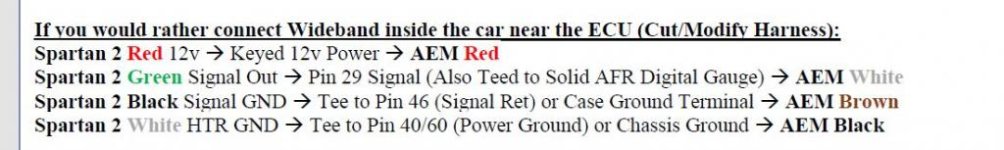

Here are the instructions with the AEM sensor added. I just don't understand how to install it yet. I'm not worried about preserving the factory harness so the best way to install is what I'm after.

--------------------------------------------------------------------

Here's the stock O2 sensor with the wideband sensor and wiring supplied.

This bag also came with the gauge and it's own instructions. Do we use this wire? There's two connections in the back of the gauge.

Here's the back of the factory O2 sensor plug. White/White/Black/Grey

Here's the back of the AEM sensor plug. Black/Grey/Yellow/Red/White

I guess I can cut the factory O2 sensor plug off and solder the new sensor into the factor plug? I just don't see where the wire colors match up. This is not making sense to me. :headscratch:

I've got some questions. I'm at the spot to install the wideband. I got the AEM gauge and sensor.

Here are the instructions with the AEM sensor added. I just don't understand how to install it yet. I'm not worried about preserving the factory harness so the best way to install is what I'm after.

--------------------------------------------------------------------

Here's the stock O2 sensor with the wideband sensor and wiring supplied.

This bag also came with the gauge and it's own instructions. Do we use this wire? There's two connections in the back of the gauge.

Here's the back of the factory O2 sensor plug. White/White/Black/Grey

Here's the back of the AEM sensor plug. Black/Grey/Yellow/Red/White

I guess I can cut the factory O2 sensor plug off and solder the new sensor into the factor plug? I just don't see where the wire colors match up. This is not making sense to me. :headscratch: